GGFI RANKED #1 AS THE BEST GRC COMPANIES IN UAE

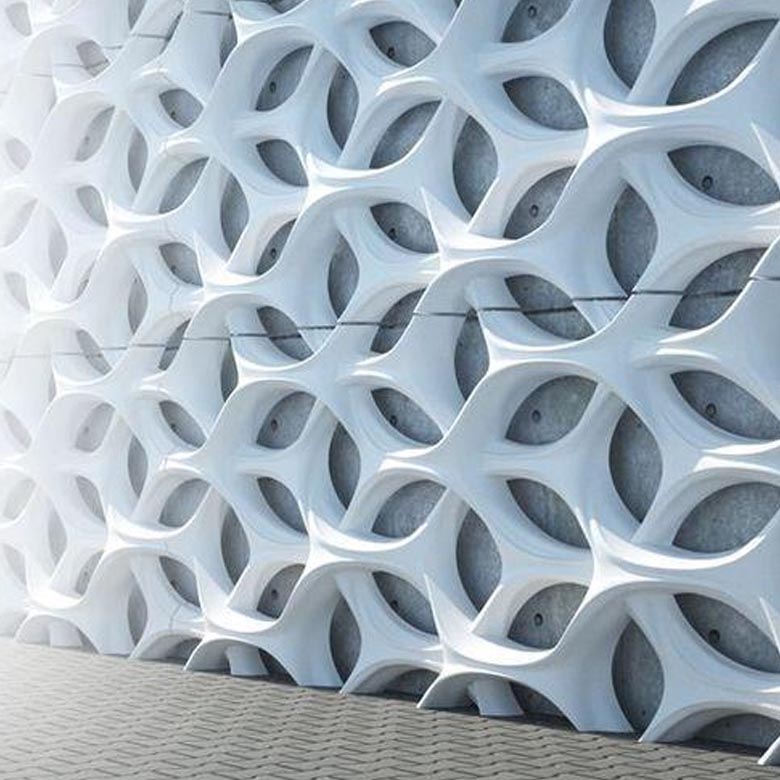

For prefabricated architectural cladding, Glassfibre Reinforced Concrete GRC or Glass Fibre Reinforced Cement GFRC is the material of choice.

GFRC or GRC is a mixture of cement, fine aggregate, water, chemical admixtures, and alkali resistant glassfibres. Globally, they are known by various names such as CCV or Composite Cement Verre, Fiber Beton, Fiber Takviyeli Beton, and GFB or Glasfaserbeton.

Globally, Glassfibre Reinforced Concrete (GRC) plays a significant role in economics, technology, and aesthetics of construction projects.

This environmentally friendly composite, with its low energy consumption and natural raw materials, is being used for a wide range of products and has gained the respect of designers, architects, engineers, and end-users for its flexible ability to meet performance, appearance, and cost parameters.

GRC has matured since it was first introduced 50 years ago in the 1960s, and today the designer has access to a variety of matrix modifiers, such as acrylic polymers, rapid-setting cements, and additives that enhance its long-term durability. A wide range of independent tests and performance data is available on all aspects of matrix formulation.

In the production of factory-finished prefabricated products using the spray process or using traditional concrete casting methods, Alkali Resistant glass fibre is typically used at 2-5% level.

Furthermore, it can also be used for reinforced renders as a site-applied mix for controlling plastic shrinkage cracking, micro-cracking, and bleeding of site-cast concrete in the 1-2% range.

German Gulf Fibreglass Industries LLC, Leading Manufacturing & Suppliers in GRC & GRP Products Since 2003.

What makes us different from other GRC Companies in UAE?

We closely follow the quality control system recommended by the Precast Concrete Institute (PCI) of the USA and Glass Reinforced Concrete Association (GRCA) of the UK. It aims to supply the UAE market with quality and affordable GRC products with high precision and consistent quality compliant to both ASTM and BS-EN code and standard.

Reliability

A consistent, regular, and high accuracy control programme is essential to the production of GRC products. From the raw materials to the finished products, proper examination, and testing, either done in-house or by third-party, and certifications from suppliers, are regularly updated to ensure the products meet the designed properties and requirement.

Experience

German Gulf has been implementing award-winning construction solutions in the UAE. Many of our team members have worked together for over 30 years, and we currently employ over 60 qualified and experienced employees. We have created tight working connections with architects, engineers, and surveyors as a result of our integrated approach to construction projects.

Environment Friendly

GRC (UAE) is consistently aware of its responsibility towards the environment and has been always working to reduce the carbon emission and to ensure a durable and safe product. Our in-house research regularly improves the quality and strength of our range of products to become better.

Frequently Asked Questions

If your question is not listed, please email us at [email protected]

For prefabricated architectural cladding, GRC / GFRC is often used as a versatile material.

With its ability to be shaped into thin, lightweight panels with a range of shapes, forms, and finishes, GRC has gained a growing reputation among architects and engineers worldwide.

GRC Panel reduces the weight load on a building’s structure because it is lighter in weight. Since GRC panels are prefabricated, they can be manufactured in the factory while the foundation and structure are being built on site.

In general, hand spray techniques are used to manufacture GRC cladding panels. Using specialized machinery, the material is sprayed into the mould. With this method, it is possible to produce panels with extremely thin, lightweight sections.

Additionally, GRC Panels are non-combustible because it’s made from mineral components. Sandwich panels with polystyrene or rockwool inserts can also be made with GRC.

GRC can easily be moulded to reproduce shapes, details, and textures.

Due to its high strength, GRC can be used to design thin, lightweight cladding elements.

GRC surfaces can be painted, glazed, and faced with natural stone.

Where weight and/or shape are problematic, GRC cladding can be used to replace non-structural precast concrete.

Support from German Gulf Fibreglass industries can be offered in a variety of ways. On a self-service basis, our shop drawings provide very clear details showing installation sequence, substrate preparation and fixing details.

GRC I GFRC stands for Glassfibre Reinforced Concrete I Glass Fiber Reinforced Concrete, which is a fine concrete reinforced with Alkali Resistant glassfibres (AR Glassfibres).